Main application areas

- Wellbore Inspection (Well jewellery, Wellhead equipment, Safety valves, Borehole nipples, etc.)

- Corrosion Inspection and Monitoring

- Wellbore Fishing Support with exact imaging of dropped object

- Inflows and Fluid Flow visualization and monitoring

- Identification of Deposits (Scale, Salt, Hydrate, etc.)

- Well assemblies for gas Storage

- Inspection of Downhole Completions (Uppers Completion, Lower Completion, Gravel Packs)

- Open Hole Imaging of Formations

- Many More…

What is your challange?

- Corrosion

(of tubing and other wellbore assembly elements) - Fishing

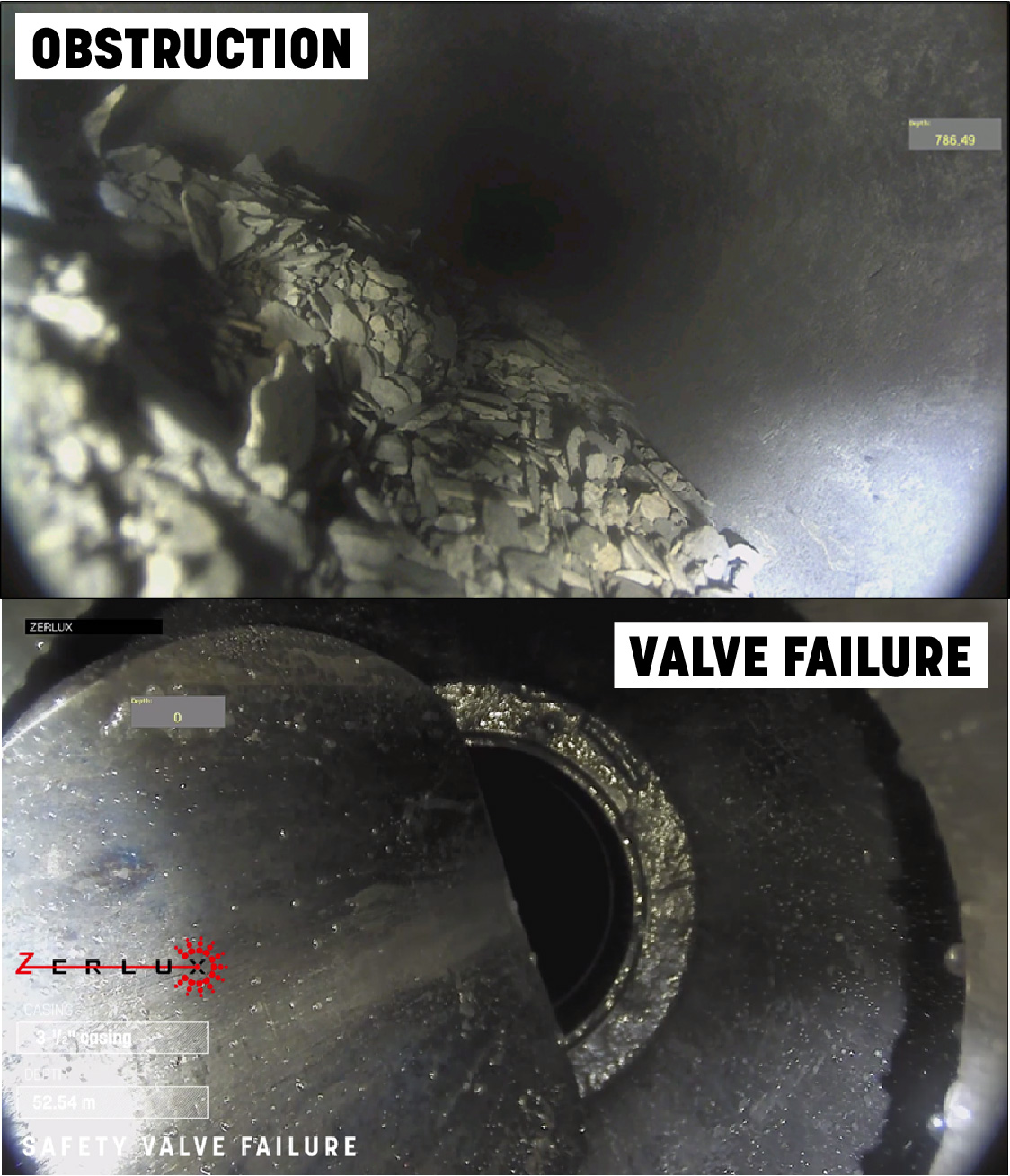

(of dropped and accidentally lost downhole tools) - Obstruction

(of inflow into the well) - Valve Failure

(of safety and regulatory/gaslift valves in the nipples or tubing-pockets) - Scale

(barite and other chemical scaling in the borehole during oil production) - Leakage

(due to isolation and fitting problems, or faulty seals)

OWING ZERLUX’S OPTEYE DOWNHOLE CAMERA

Zerlux proud itself as a reliable and user-friendly camera company selling its inhouse range of OptEye Hybrid Cameras across the globe along with training and operational support. We are always available to resolve queries from our customer.

An immediate access of OptEye Hybrid Cameras to our customer along with in-depth training program. We help customer to reduce operational cost and make them independent from all dependencies on third party.

Our goal is to make OptEye Hybrid Cameras accessible for use at their disposal by our customers.

Our OptEye Downhole Camera Family for sale provide:

- Range of hybrid cameras to choose from per requirement

- Coiled tubing cameras along with lens cleaning technology

- Custom designing for optimized operational efficiency

- Procedures support for running and well-clean out

- Support for training, demonstration job and SIT

- On request Field Personnel for operating OptEye Downhole Camera

- On request Job Interpretation by experienced Field Engineers

Main application areas

- Wellbore Inspection (Well jewellery, Wellhead equipment, Safety valves, Borehole nipples, etc.)

- Corrosion Inspection and Monitoring

- Wellbore Fishing Support with exact imaging of dropped object

- Inflows and Fluid Flow visualization and monitoring

- Identification of Deposits (Scale, Salt, Hydrate, etc.)

- Well assemblies for gas Storage

- Inspection of Downhole Completions (Uppers Completion, Lower Completion, Gravel Packs)

- Open Hole Imaging of Formations

- Many More…

Downhole Camera Achived Milestones

2016

Prototype 2.125”, Full HD, 117 degC rated Fiber Optic Camera

2017

Commercial Jobs of Fiber Optic Downhole Camera in Europe

2018

Released High and Low Temperature, 2.125”, Full HD Slickline Memory Camera

2019

Global Operational Footprint in Continental Europe, North Sea, Far Asia with 2.125” Hybrid Camera

2020

High Temperature and 1.732” Standard Hybrid Camera

Operational Footprint in Gulf (GCC) Region2021

Sales Model for OptEye Downhole Cameras

High Temperature, 1.732” Standard Hybrid Camera

High Temperature, 1.732” HD Hybrid Camera

CTU Lens Cleaning Camera2022

High Temperature, 1.732”, 360°HD Sideview Hybrid Camera

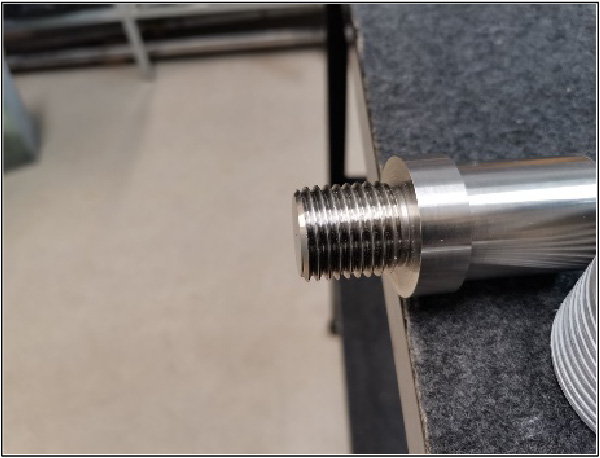

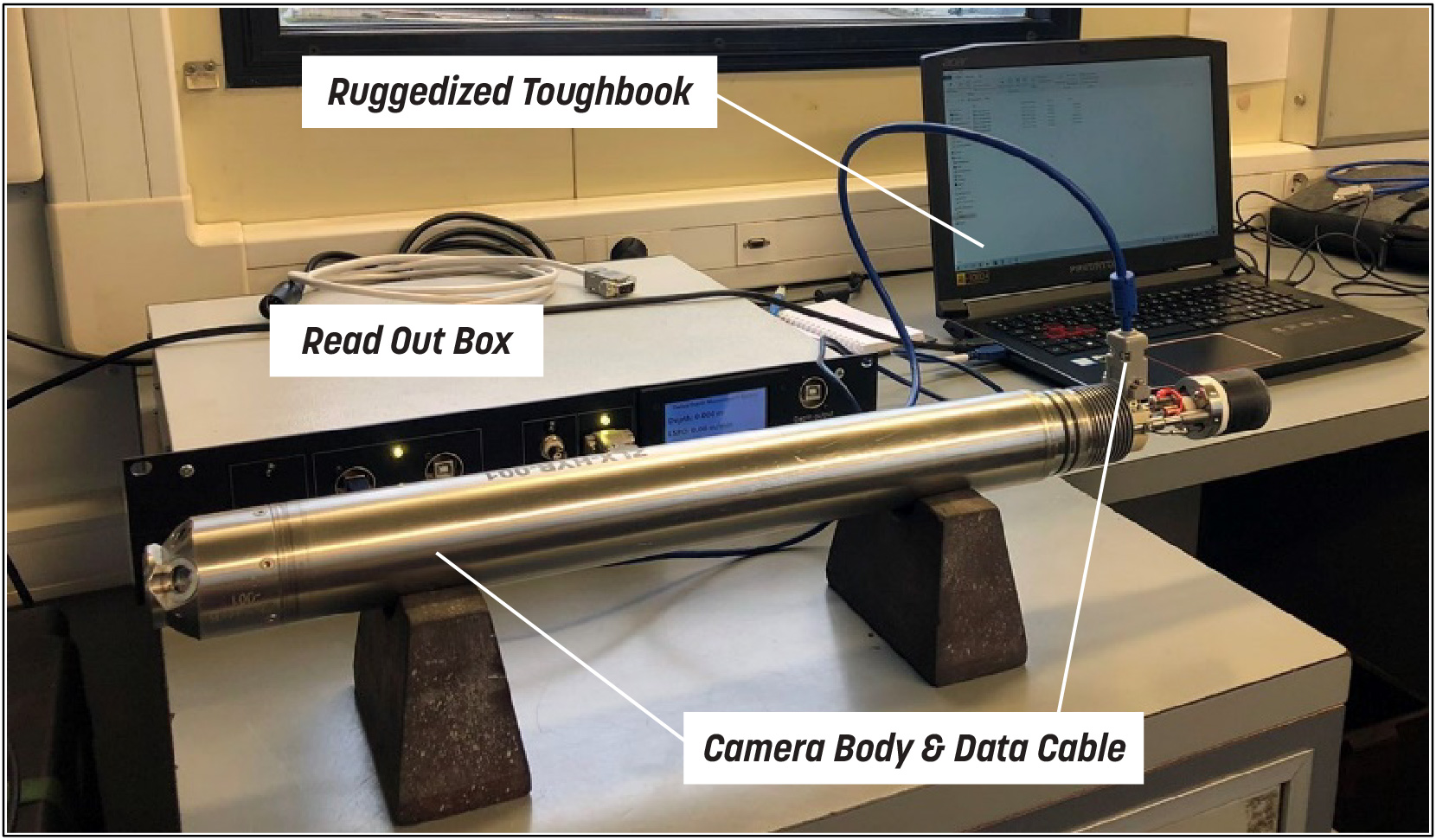

Typical Downhole Camera Bottom Hole Assembly

- Crossover/Weight bar/Jar etc.

- Body Slip-over Centralizer

- Downhole Camera Body

- Camera Lens & LED

Top Connections

Surface Read Out (SRO)

Interested more? Check other case videos!

Milestones

- highest wellbore

temperature 171°C

171°C - highest wellbore

pressure 558 bar

558 bar - deepest wellbore

rih 6158 m

6158 m - audited quality

management system ISO 9001

ISO 9001 - successful

jobs 100+

100+ - successful operations

off-shore 50+

50+